Short take: repairing a mono speaker plug

A little bit of solder and a new plug to make things right

I’m now using a lovely, big speaker for the ANR100 AllStar node on my desk, an old Heathkit HS-1661.

The audio from that big speaker is rich and smooth. It is a pleasure to use.

However, the speaker plug looked like something every ham radio operator has seen: a plug without the original cover, with heat shrink tape substituting for the plug cover. I couldn’t see if there were loose, stray wires in there because of the tape. Like many other hams, I’ve done this myself when I didn’t have the right bits for a better complete repair.

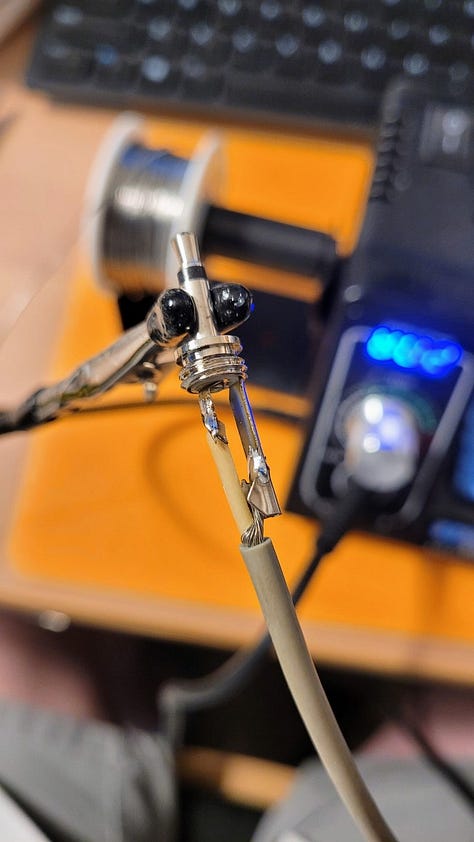

I cut the tape off and found what I view as too much wire without the shield/ground around it, so I cut off the old plug, prepared the wire on the freshly cut end, and soldered on a new plug. (I have a lot of radio frequency interference at my location so any opportunity to reduce RFI is welcome.)

I added some heat shrink tubing to take a bit more strain off the connection and make the plug a little easier to find in dim light. I couldn’t put my hands immediately on my heat gun to shrink the tubing so I used my rework station.

This isn’t much of a repair but it was satisfying to improve that part of the system.